Wooden cutting boards. Everybody loves them, but there is a lot of confusion and misunderstanding about the different types of wooden cutting surfaces available. In this post, I’m going to explore the differences between a “cutting board” and an “end grain butcher block.”

Let’s start by learning a little about wood grain and I’ll use a paint brush to help illustrate. Think of the bristles in a paint brush as the grain (or fiber) in a piece of wood. So, if a tree is standing upright the grain is oriented vertically.

After a tree is cut down, the fibers are oriented horizontally. So, when the tree is sliced and cut into useable pieces, you get pieces of wood with the grain oriented horizontally.

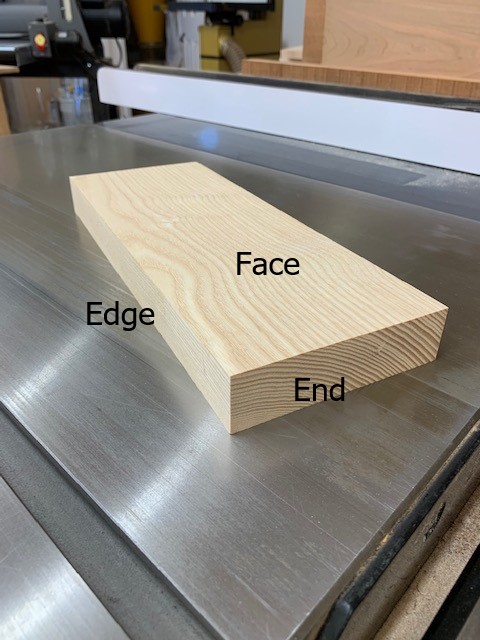

Now let’s look at the terms used to describe grain orientation. In the context of wood grain, every board has three different surfaces.

So, every board has a face grain surface, an edge grain surface, and an end grain surface. You can make a wooden cutting surface with the grain situated in any one of these three orientations. Here is a face grain cutting surface (the pieces are glued with the face grain up forming the cutting surface).

Here is an edge grain cutting surface (the pieces are glued with the edge grain face up forming the cutting surface).

These two cutting surfaces look similar, but the grain is oriented slightly differently. However, these two surfaces are similar in one important respect. Face grain and edge grain cutting surfaces are both “long grain” surfaces – because the grain is running lengthwise along the cutting surface. An end grain butcher block, however, is very different.

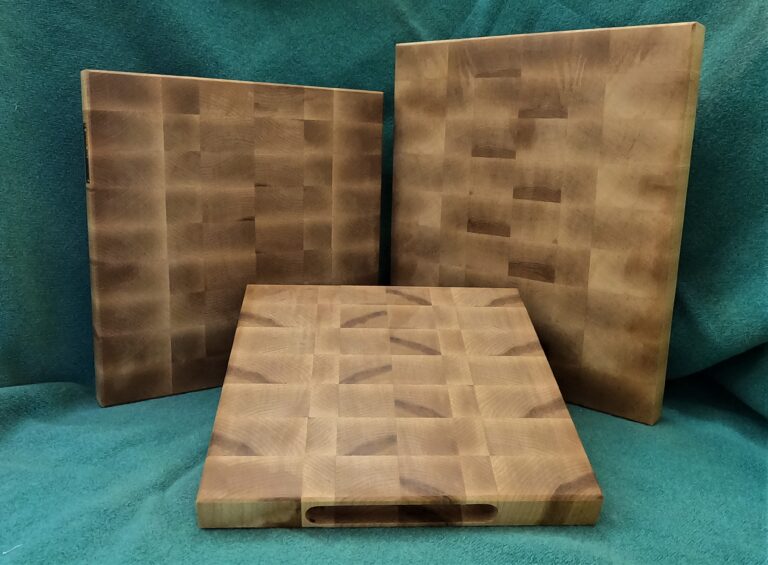

It looks very different because the end grain is facing up. However, the difference between a long grain cutting board and an end grain butcher block is about much more than simply the way they look. Let’s go back to our paint brush to illustrate the difference. If you’re cutting and chopping on a long grain surface, you’re cutting across the wood fibers.

Just like cutting across the bristles of a paint brush can cut or damage the bristles, cutting and chopping on a long grain wood surface can damage the wood fibers. An end grain cutting surface, however, works differently. When you cut on the end of a paint brush, the knife just slides in between the bristles.

Likewise, when you cut and chop on an end grain surface, your knife is going in between the wood fibers. This is significant for two reasons. First, compared to a long grain surface, an end grain surface is less likely to get damaged or gouged. Also, cutting and chopping on an end grain surface is easier on your knives.

This doesn’t mean that long grain cutting surfaces are “bad,” only that there are differences between a long grain surface and an end grain surface. Everything else being equal, an end grain surface is going to last longer and help your knives stay sharper longer.

So, how do you actually make these things? Making a long grain cutting board (like the two shown above) is straightforward. Mill and cut wood pieces in the size and dimension you like and glue them together in either a face grain or edge grain orientation. When the glue dries, clean up the surface, trim it to final dimension, and you have a long grain cutting board.

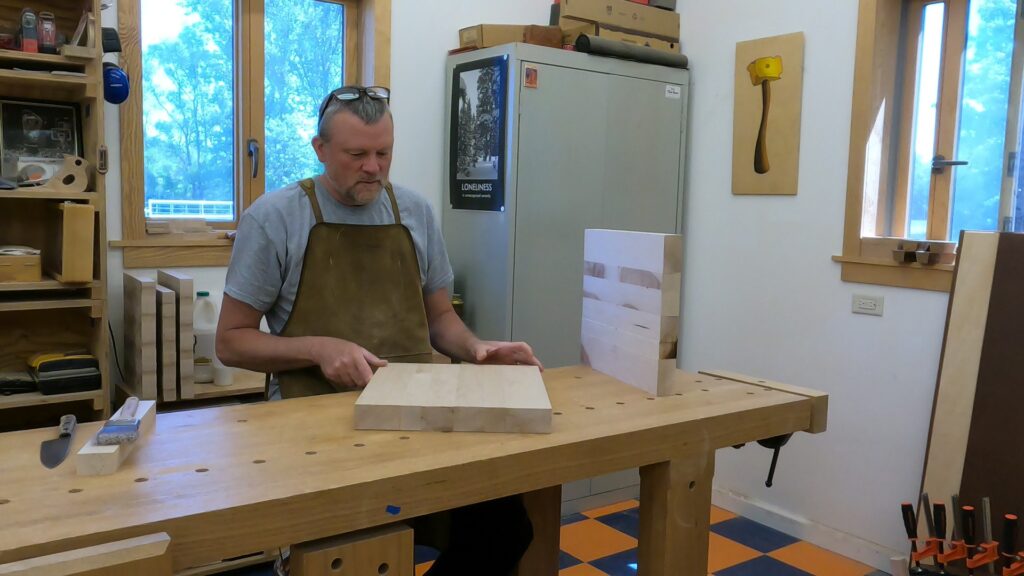

To make an end grain butcher block, you first make a long grain cutting board.

Then you cut the long grain cutting board (across the grain) into several strips.

Then, you rotate each of these strips 90 degrees so that the end grain goes from facing out to facing up.

You glue these pieces together and you get an end grain cutting surface. Now, just clean it up and cut it to final dimension.

This is a very basic description how you make long grain cutting boards and end grain butcher blocks. However, if you’ve ever shopped for a wood cutting surface, you know that there is a significant price difference between a long grain cutting board and an end grain butcher block.

For example, Boos Blocks is a popular brand. They make long grain cutting boards and end grain butcher blocks. Their long grain cutting boards sell for $100-$150 (or more). However, their similarly sized end grain butcher blocks sell for $250-400 (or more). So, why the dramatic price difference? The short answer is that making an end grain butcher block requires much more time and effort. It is also more difficult to “finish” or clean up an end grain surface (i.e., get the surface flat and smooth).

In conclusion, for cutting and chopping, an end grain cutting surface is generally a better choice than a long grain surface. However, depending on your use, the difference may not be dramatic. Moreover, any quality wood surface is a better choice than plastic or other non-organic material. In short, it’s hard to go wrong with a quality wooden cutting surface, but whether you choose a long grain cutting board or an end grain butcher block is a matter of personal preference.

I’ve been making end grain butcher blocks for more than 15 years, but have recently begun making long grain cutting boards and work surfaces as well. I’ll have a blog post up in the near future showing some of the creative things I’m doing with long grain boards. At the moment, however, I am focusing on end grain butcher blocks. I currently have a handful of end grain butcher blocks available for purchase. Go to my “marketplace” page (link) and see what’s available. I’ve also started work on another batch of butcher blocks that will be ready for the holidays. As always, thanks for your interest. If you have any questions or comments, please send me an email or a message via Facebook.

The end grain story makes sense to me.